Jiangsu tandge Environmental Engineering Co., Ltd. (hereinafter referred to as tandge) is a high-tech enterprise based on scientific research, committed to the development and achievement transformation of practical technologies for energy conservation and environmental protection, and determined to develop globally. The company is a "high-tech enterprise in Jiangsu Province" specializing in the design, manufacture and installation of various environmental protection machinery, environmental protection engineering, thermal energy and thermal engineering, with a construction area of nearly 30000 square meters. It is mainly engaged in the design, production and installation of various large-scale high-efficiency electrostatic precipitator, bag dust remover, electrostatic bag composite precipitator, complete sets of waste heat recovery products of industrial furnace (kiln) and complete sets of ion desulfurization products. The company has the general contracting qualification of environmental protection, and has established "Engineering Technology Research Center for industrial furnace flue gas treatment and waste heat utilization" and "Jiangsu enterprise academician workstation".

Tandge's endless exploration of science is the embodiment of its professionalism. No matter in the face of difficulties and setbacks, or success and joy, tandge always adheres to its goals and beliefs, that is, it is committed to developing safe, energy-saving, efficient and environmental protection heat energy and environmental protection technologies, constantly eliminating itself, pursuing higher and new technologies, contributing to the construction of harmonious China, saving China and the progress of human society. The main products of Tianjie environment company include TGB series long bag low-pressure pulse bag dust collector, BQM series air box pulse bag dust collector, LFEF glass fiber large bag dust collector, blast furnace gas dry dust collector, TGD electrostatic dust collector and powder concentrator, with more than 80 specifications and varieties.

Jiangsu Tianjie Environmental Engineering Co., Ltd. / Jiangsu Tianjie environmental protection equipment Co., Ltd

Headquarters address: 19 / F, China Construction Building, No. 58, Jiefang South Road, Yancheng City

Tel: 0086-515-88580288

Fax: 0086-515-88580266

Email: jstjgs@163.com

Website: m.zgmeimei.cn com

More Details

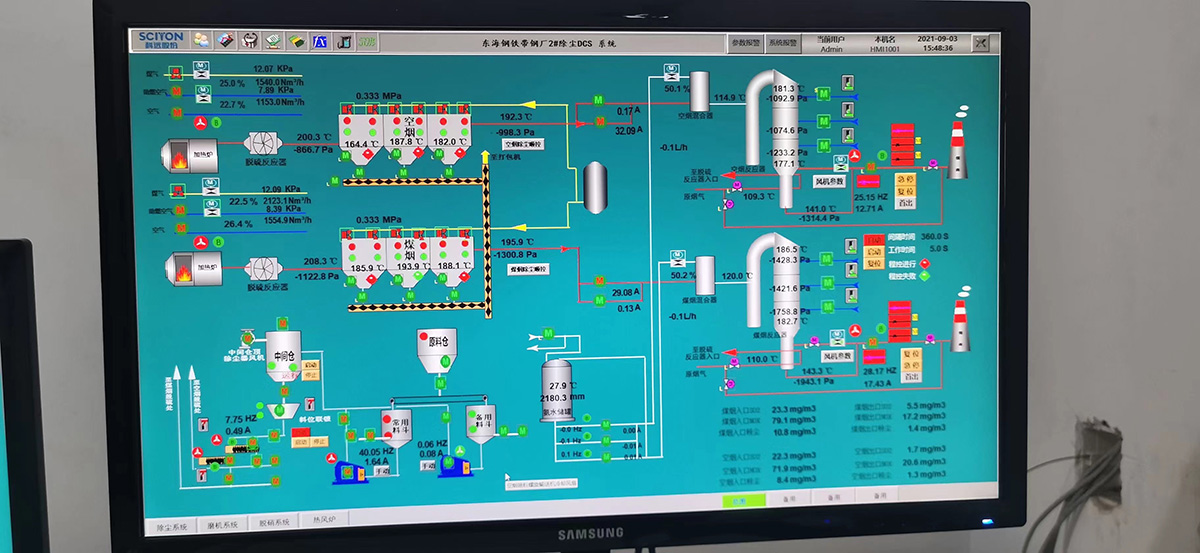

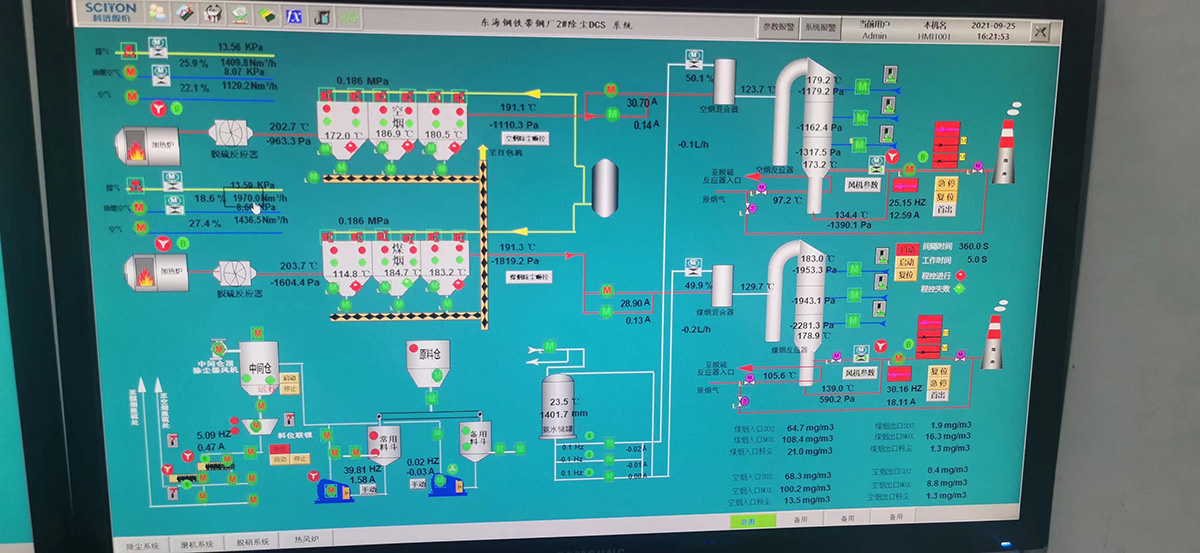

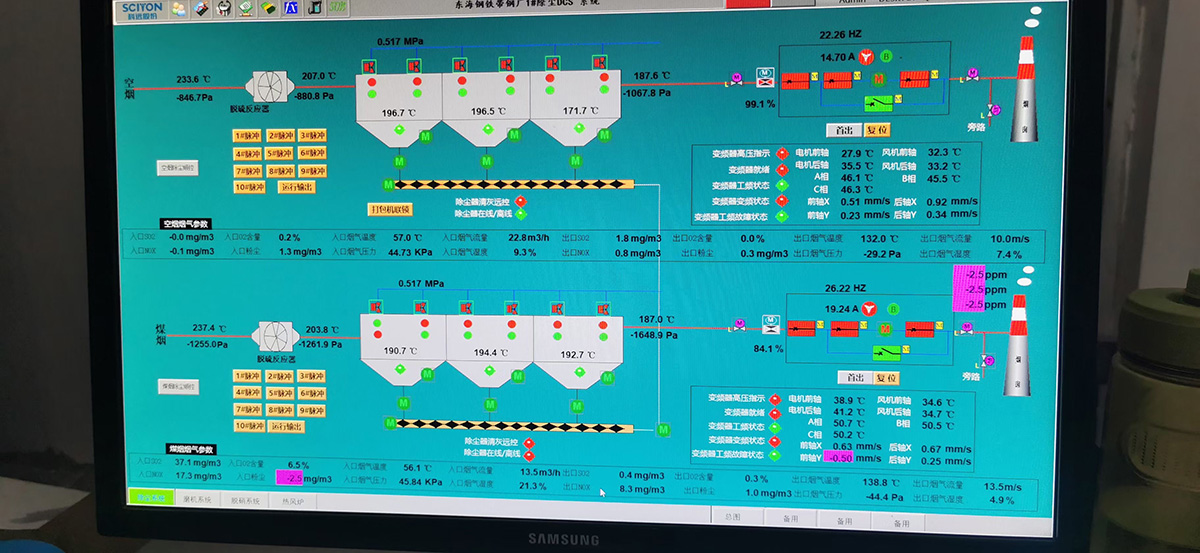

Intellectual property name: a desulfurizer cyclone mixing device

Corresponding product or project: Tangshan Donghai iron and steel sintering plant project

Core technology: the flue gas from the heating furnace enters the sodium based (NaHCO3) dry desulfurization (sodium based dry) dust removal integrated system. The flue gas is led out from the outlet of the original induced draft fan, and the flue gas heat exchanger is set. The heated high-temperature flue gas is used to heat the soot. The hot flue gas after heat exchange is mixed with the air flue gas to improve the flue gas temperature and meet the reaction temperature requirements of desulfurization and denitration. After passing through the SDS desulfurization and dust removal device, it is led back to the original flue gas for discharge. Two sets of soot desulfurization and dust removal devices and two sets of air smoke desulfurization and dust removal devices are built respectively in 1580 steel rolling line; The flue gas first enters the sodium based dry desulfurization reactor, and the sodium bicarbonate ultra-fine powder is injected into the sodium based dry desulfurization reactor. The sodium bicarbonate ultra-fine powder decomposes into highly active sodium carbonate and carbon dioxide under the action of high-temperature flue gas. The highly active Na2CO3 is fully contacted with SO2 and other acidic media in the flue gas to produce chemical reaction and be absorbed and purified. After desulfurization, the powdery particle products enter the bag filter with the air flow to collect the desulfurization by-products.

Technical indicators achieved: the emission concentration of waste gas particulate matter is less than 10mg / Nm3 (dry basis), which is guaranteed by the original dust removal system. The emission concentration of sulfur dioxide is less than 35mg / Nm3 (dry basis), and the concentration of nitrogen oxides does not increase.